Compressors frequently have to handle changing flow rates, either due to air production variation or air consumption changes. Air compressor output varies according to varying ambient conditions and air consumption varies according to varying demand patterns.

Various capacity control methods are used in positive displacement and volumetric displacement compressors, which include following.

Capacity control for positive displacement compressors:

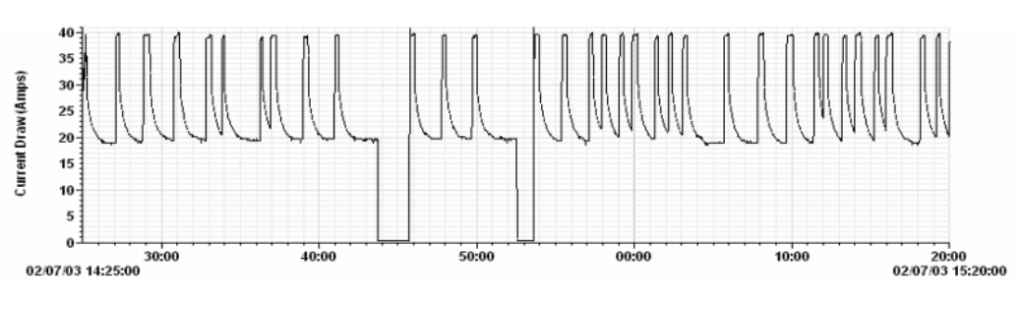

- On/off: compressors are powered on or off as per demand. This is possible in small capacity compressors wherein there is less stress on electrical and mechanical components.

- Suction modulation: the inlet valve opens and closes proportionately to match supply to demand as sensed by a pressure transmitter. The inlet valve moves continuously and immediately in response to changes in the sensed pressure to let restricting the air intake to control flow capacity. Throttled inlet is simple and relatively efficient at 60 to 100% load.

- Spiral valve or turn valve or variable displacement: are used primarily in lubricated rotary screws. The controls are also called geometric, rotor length adjustment and the like. These controls match output to demand by modifying or controlling the effective length of the rotor compression volume. There are two common versions of variable displacement for capacity control between 50% to 100%.

The spiral-cut high-lead valve opens or closes selected ports in the compressor cylinder. The ports located at the beginning of the compression cycle see low pressure. Opening these ports even a small amount prevents any compression until the rotor tip passes the cylinder bore casing that separates the ports. This effectively reduces the volume of trapped air to be compressed, and the horsepower required to do it.

The poppet valve control uses some form of poppet to open and close the ports. The poppet valve control operates much the same way as the spiral or turn valve except the control ports are opened and closed by a double-acting poppet valve. This reduces the amount of compressed air leakage at the higher load conditions by creating a moving seal off point without any significant cavity to hold high-pressure air.

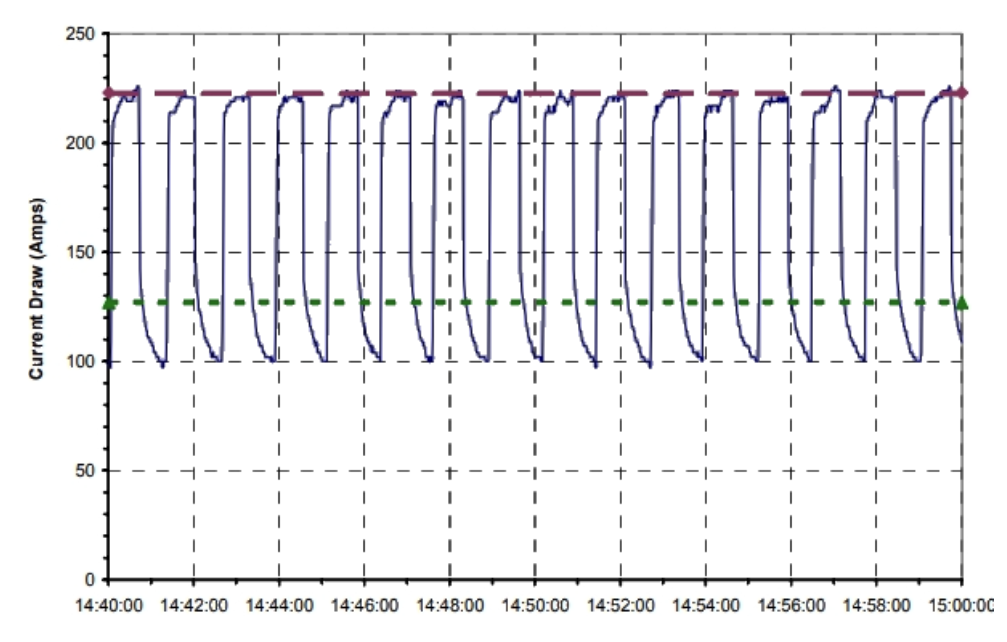

- Load / no load: The most common is two-step control, which keeps the compressor inlet either fully open or fully shut. Over the complete operational band, the unit is at full load from the preset minimum pressure point (load point) to the preset maximum pressure (no load point). In case of Reciprocating compressor about 15% to 20% power is consumed in fully unloaded or idle run. In case of Screw compressor about 30% to 35% power is consumed in fully unloaded or idle run.

- Multi-step controls: In a three-step control, the capacity is controlled at 0% – 50% – 100%; similarly in case of five-step control, the capacity is controlled at 0% – 25% – 50% – 75% – 100%.

- Load/Unload with auto shut off:

- Variable frequency drives vary the speed (rpm) of the electric drive motor as per air demand to proportionately increase or decrease the air flow output of a compressor. VSD converts the input power supply frequency from AC to DC and again into AC, but at desired frequency. There is a loss of power to the tune of 2% to 3%, hence this type of capacity control is not efficient when the compressor is operating mostly near the full load or 100% capacity. Further, there could be some issues with harmonics, bearing currents in motors with retrofitted VSD.

- Chart showing % Power v/s Capacity Control methods

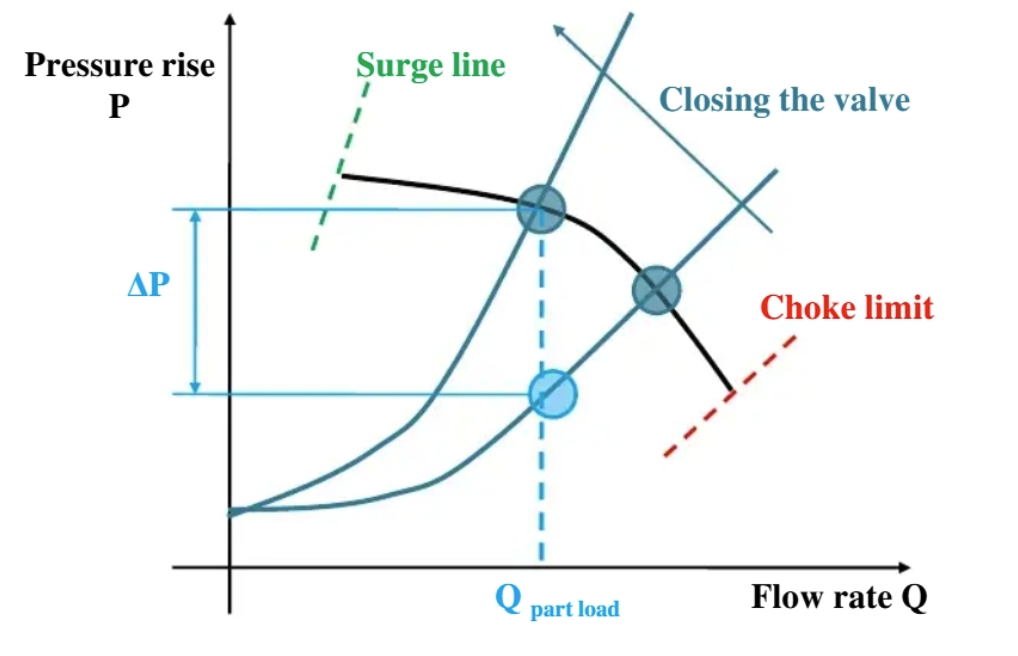

Capacity control for Volumetric / centrifugal compressors:

- Load / Unload

- Bypass to suction

- Suction modulation (IBV or IGV)

- Blow-off (or Constant pressure)

- Auto-dual

- Speed (RPM) variation

Suction modulation:

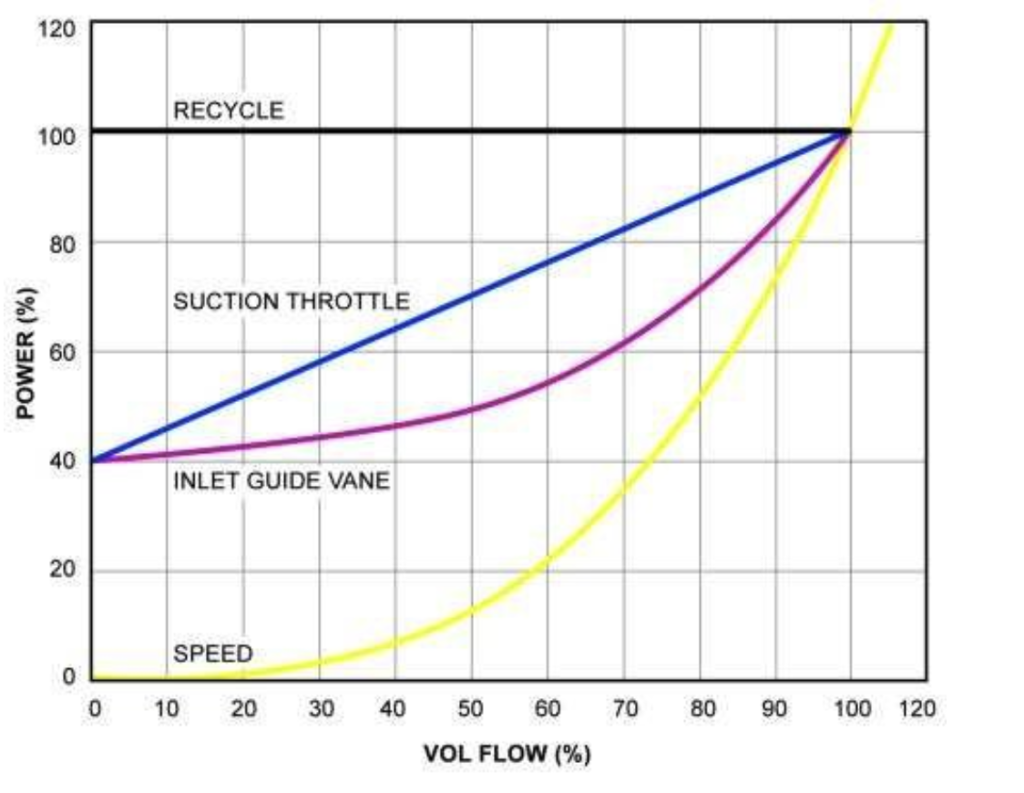

Inlet Butterfly Valve (IBV): The Inlet Butterfly Valve may be driven electronically or pneumatically, and as it closes it creates a pressure drop across the valve, effectively reducing the inlet pressure into the compressor and throttling the compressor’s ability to make pressure and subsequently flow.

Inlet Guide Vanes (IGV): The Inlet Guide Vane control has much better performance as compared to IBV. IGVs may be driven electronically or pneumatically and are a series of radial blades arranged in the intake. These vanes, in the wide-open position, are parallel to the airflow, and at fully closed are at 90 degrees to air flow. As the guide vanes are rotated from full open to partially closed, they cause the drawn-in gas to rotate in the same direction as the impeller. These pre-swirl changes the incidence angle of the incoming air as it approaches the inducer section of the impeller, effectively reducing the energy required to produce pressure and flow. The use of IGV’s can effectively throttle the compressor with the added benefit of being more efficient. Depending on where you are operating on the compressor curve, a user may see up to a 9% efficiency gain over standard IBV throttling. The load set point of a centrifugal compressor is typically at a given pressure so when the system pressure falls below a given level the compressor will load.

Blow-off (constant pressure) – The constant pressure control system is designed to continuously control the air output while keeping the net pressure fluctuations to a minimum, which is critical in some applications. Controller uses combination of IBV / IGV and Blow-off valve on the discharge line based on pressure signal feedback. As the demand reduces, thereby raising the discharge pressure, the IBV / IGV closes gradually. Despite fully closing and still the pressure keeps rising, the Blow-off valve gradually opens to let off the air to atmosphere to maintain a stable discharge pressure. This is energy in-efficient control and may be employed for critical stable pressure applications.

Auto-Dual – Controller uses combination of suction modulation and unload to control the capacity. Controller initiates the regulation by means of IBV or IGV. At the minimum throttle position, the IBV or IGV stops closing action, allowing the discharge pressure to rise to the unload set point. At this moment the compressor unloads, IBV or IGV closes, and an unloading valve fully opens.

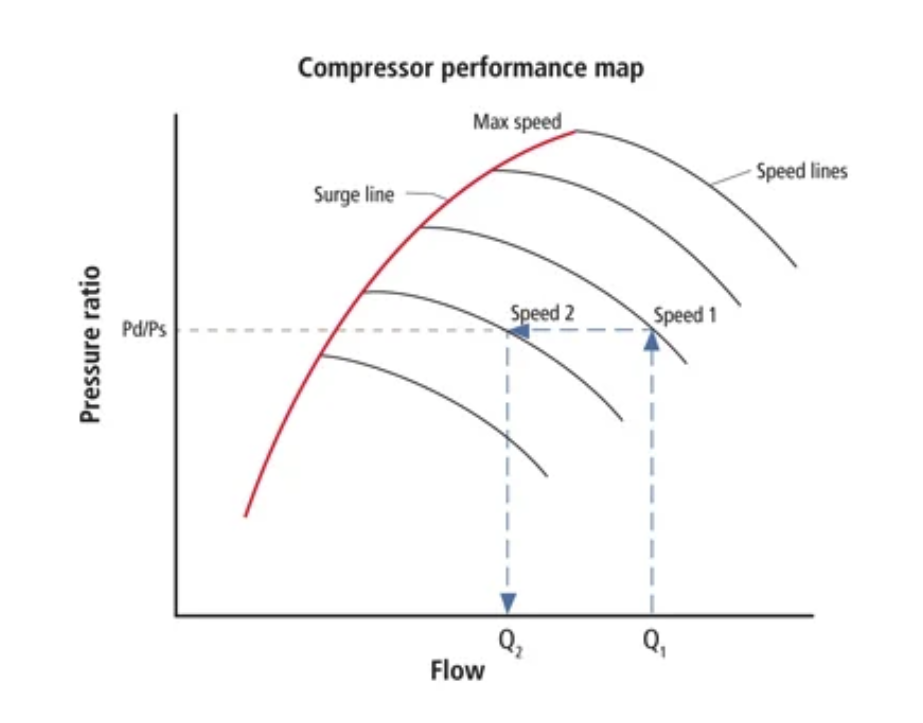

Speed Variation – The most efficient method to modulate the capacity of a compressor is to vary its speed. Speed modulation makes full use of the Fan Law (for a constant diameter impeller), which state that flow is proportional to the speed of the machine, pressure or head is proportional to the square of the speed and power is proportional to the cube of the speed. Thus, the highest turndown is possible with speed variation, compared with other method of capacity control, and this allows for the most efficient energy reduction when the process load drops.

This method requires a much higher investment (capital costs) to provide the variable speed drive system for the compressor and may involve higher maintenance costs than all other methods, but the energy savings over the life-cycle of the plant can justify this when the air demand is variable.

Chart showing comparison of power consumption in various types of capacity controls in centrifugal compressors: